Custom High Precision Tungsten Heavy Alloy Fabrication Service Square Cnc Turning And Milling Machine

Grade:

W1 WAl1 WLa WCe

Standard:

GB/T4187-1984

Surface treatment:

Black, alkaline wash, car polish, polished

Color:

Metallic color

High-density tungsten alloy rods & tungsten alloy bars shave large specific gravity, high strength, and strong ability to absorb rays. XK Metal can customize high-density alloys in various shapes and sizes according to your requirements.

Tungsten Alloy Rod / Bar Specification

• Diameter: 2.0-100.0mm

• Length: 50-1000mm

• Density: 16.5-18.75 g/cm3

• Composition: W content: 85-99%, W-Ni-Fe, W-Ni-Cu

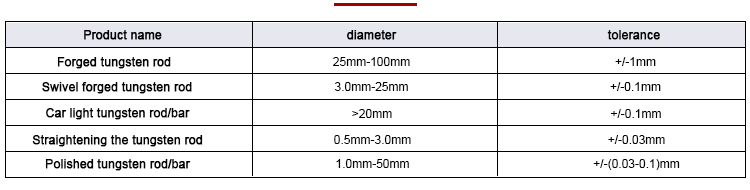

Tolerances allowed for tungsten alloy bars

Applications for Tungsten Alloy Rod / Bar

High-density tungsten alloy rods & tungsten alloy bars are especially suitable for automobile counterweights. Drill one or more holes with a diameter of 25/64 or larger on the module, and then fill in the required number of tungsten alloy cylinders. Then insert a 3/8 inch long pin into the hole. The product can also be processed into military products, molds and various counterweights, such as speedboat counterweights, vehicle counterweights, aircraft counterweights, helicopter counterweights, ship counterweights and tank counterweights, etc. . Generally, tungsten alloy cylinders are used in the military industry and can also be used as molds and various counterweights.

Consulting Engineers

Give our technical sales team a call or contact us via email

Phone/Whatsapp : +86 15814459429

Email: [email protected]