HD cutting

machining

Abrasive saw

band-saw

Heat treatment

welding

Waterjet

Precision instruments

shearing

laser cutting

HD plasma cutting and beveling

Let us use the most advanced high-definition plasma cutting and beveling equipment to prepare the bevel for your nickel alloy plate shape and welding. We can handle squares, rectangles, strips, circles, rings, and custom for each printed shape.

By letting us prepare bevels for your V, K, X and Y welding, reduce bottlenecks and save time, materials and welding wire.

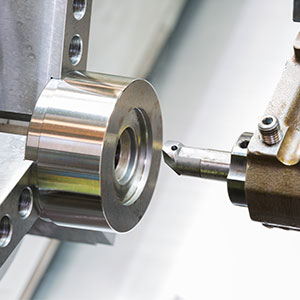

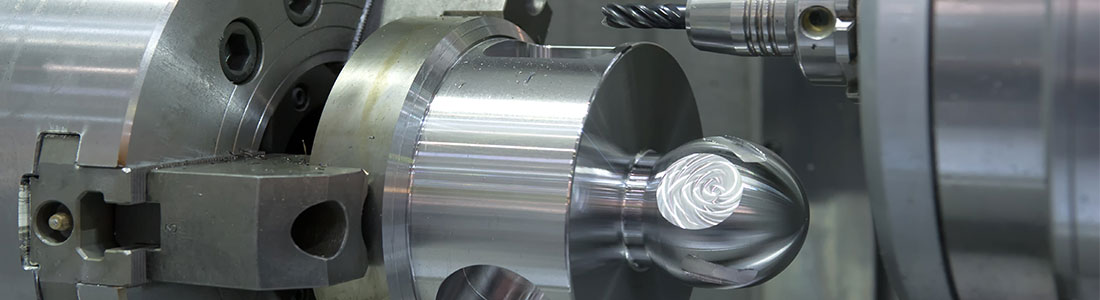

CNC precision machining

Our machining workshop can process from conventional parts to complex multi-dimensional tight tolerance parts. We have expertise and experience in high nickel alloy components.

Corrosion Materials specializes in providing custom components for many industries. We can process, drill, tap, turn, drill, bevel and thread. We can provide customers with single-use single parts for emergency or prototype and mass production of thousands of parts.

Some of the many components we provide are: plugs, nozzles, bolts, nuts, caps, block fittings, sprayers, glands, sleeves, filters, valve bodies, sight glass assemblies and instrument bodies.

Abrasive saw

We have abrasive saws for cutting small diameter rods or hollow lengths. Our full-automatic sawing machine guarantees the cutting precision. At the same time, the number of teeth and tooth shape of the saw blades we use match the material we cut. Only when the details are done can the processed product achieve the desired effect.

Band-saw

Our CNC band saw can effectively process the bar to your length.It is mainly used for the CNC cutting of round steel, square steel, aluminum ingot, round ingot, aluminum profile, profile steel, plate and other non-metallic materials of graphite, carbon, poly-monocrystalline silicon, and can reach the level of imported similar equipment.

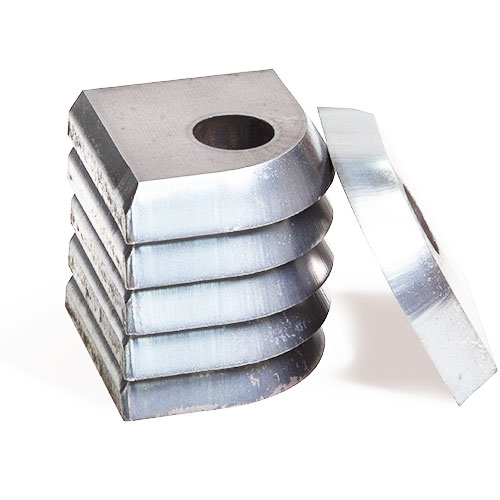

Heat treatment

Metal heat treatment is one of the important processes in mechanical manufacturing. Compared with other processing technologies, heat treatment generally does not change the shape and overall chemical composition of the workpiece, but by changing the microstructure inside the workpiece or changing the chemical composition of the surface of the workpiece , To give or improve the performance of the workpiece. Its characteristic is to improve the internal quality of the workpiece, which is generally not visible to the naked eye. In order to make the metal workpiece have the required mechanical properties, physical properties and chemical properties, in addition to the reasonable selection of materials and various forming processes, heat treatment processes are often indispensable.

welding

Our internal welding tools have the experience required to weld corrosion-resistant alloys. We focus on providing components and sub-components for various industries. We manufacture our own accessories and customized accessories according to your drawings. We usually provide distributors, spools, small containers, vanes, custom fittings, nozzles and other custom welding components for various industries. We provide tests of ANSI, ASTM and ASME specifications.

Water jet cutting

Water cutting, also known as water jet, is a high-pressure water jet cutting technology. It is a machine that uses high-pressure water to cut. Under the control of the computer, the workpiece can be cut arbitrarily, and it is not affected by the material texture. Because of its low cost, easy operation, and high yield rate, water cutting is gradually becoming the mainstream cutting method in industrial cutting technology. The water jet can cut all kinds of thick and hard materials: such as stainless steel, aluminum, copper, steel, marble, alloy metal, glass, plastic, ceramics, tiles and various visible materials. The accuracy of cutting workpieces is between 0.1mm and 0.25mm. The accuracy of the workpiece is determined by the accuracy of the machine, the size and thickness of the workpiece to be cut.

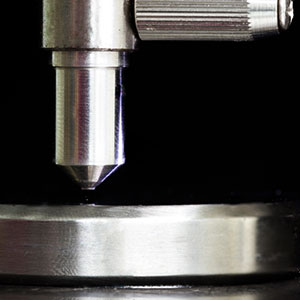

precision instrument

We provide a variety of precision instrument services, including bending, tensile, corrosion and X-ray testing to meet uncompromising requirements such as ANSI, ASTM and ASME.

Shearing

We have shearing capabilities for sheet and plate. Depending upon the thickness and application, we can shear rectangles, squares and strips per your requirements.

Laser Cutting

We can provide parts with intricate patterns, holes and slots at close tolerance with CNC laser cutting. We can cut standard shapes from plate and sheet such as rectangles, squares, circles, rings and strips in addition to cutting your custom per print shapes with and without holes and slots. Laser cutting is particularly beneficial for cutting heat exchanger baffle plates. Send us your drawing and we can quote per your requirements.