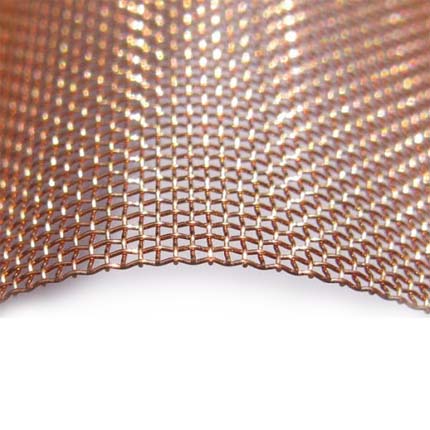

Copper Cu alloy Wire, Copper supplier

Grade:

C51000 C52100 C51100

Standard:

Various diaphragms, capsules, bellows and springs in the instrument industry

Surface treatment:

Obtain high elasticity and strength after failure, and corrosion resistance, weak magnetic

Color:

Reddish brown metal

The XK Metal Company has developed a series of high-strength and high conductivity chromium zirconium copper alloy, high-strength and high-wear-resistant bronze alloy, medium strength and high plasticity brass alloy, etc..3These high-precision Copper alloy wires ,used in more than 20 industries such as aerospace, automobile industry, shipbuilding industry, 5G communication, consumer electronics, etc., continuously creating value for global customers.

Material for elastic terminal elements C51000 Copper alloy Wire

Materials for elastic terminal elements C51000 Copper alloy Wire developed by XK metal has high strength, elasticity, wear resistance and diamagnetism.It has good pressure processability under at normal temperature, high fire resistance to electric spark, good weldability and is corrosion resisting in atmosphere and fresh water. The product has bright and tidy surface, which is smooth when observed under a 40X microscope. The dimensional accuracy can be controlled within 0.005mm. XK Metal adopts automatic spooling equipment to ensure good material evenness, meeting the high-speed pay off requirement of customers. Surface quality of the material can meet the requirements of electroplating process of tin, nickel, copper, gold, platinum and other elements, and the surface after electroplating is smooth without color difference; C51000 Copper alloy Wire has good bending performance. It can be bent to 90° for 6 times without breaking.

High strength and high wear resistance alloy materials for automobile industry C52100 Copper alloy Wire

C52100 Copper alloy Wire developed by XK Metal are mainly used in automobile industry. These two materials have the characteristics of high torque, high wear resistance and high strength. In harsh working environment, they can withstand a working temperature of about 200℃ and maintain the material characteristics under fierce vibration and serious wear. The material has stable chemical composition, and the impurity content is strictly controlled, reducing the influence on the resistivity fluctuation, ensuring that the electric signal transmission is not distorted, and meeting the sensitive and efficient work of the automobile industry.

High strength and high elasticity alloy materials C51100 Copper alloy Wire

The high strength and high elasticity alloy materials C51100 Copper alloy Wire developed by XK Metal adopt high-purity raw materials and with fully automatic equipment , thus realize uniform structure, stable performance and good cold forming performance. They are suitable for aerospace, high-speed train, automobile industry and other fields.

If the material you are looking for is not listed above, it does not mean that we can't provide it. Please be sure to contact us by email or phone, and we will give you an accurate reply within 24 hours.

Consulting Engineers

Give our technical sales team a call or contact us via email

Phone/Whatsapp : +86 15814459429

Email: [email protected]