Aluminum nitride ceramic , Aluminum supplier

Grade:

1A99 1A97 1A95 1A93 1A90 1A85 1080 1070

Standard:

GB/T3190-1996

Surface treatment:

Grinding

Color:

White/Gray

Product Brand: Xinkang Ceramics

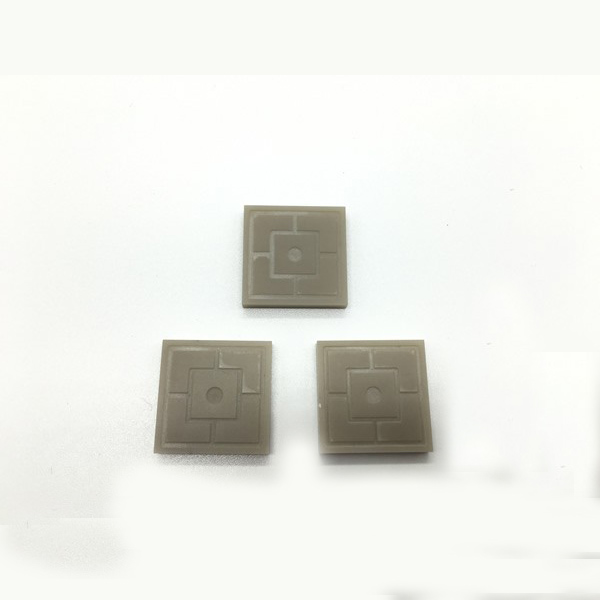

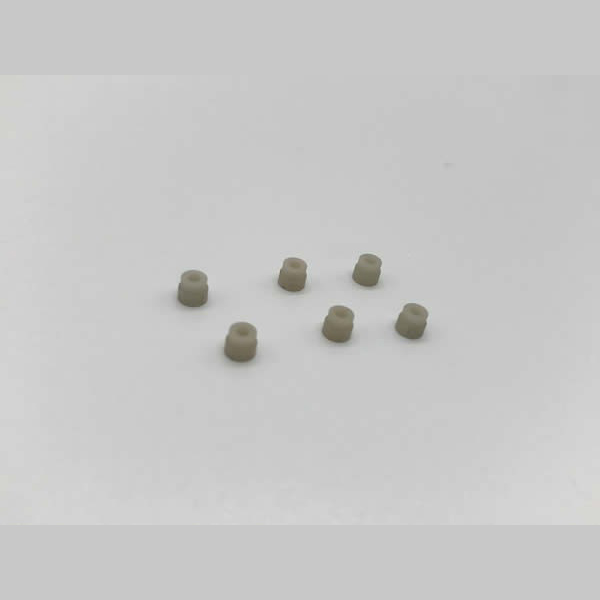

Ceramic material: aluminum nitride ceramic

Performance:

The sublimation decomposition temperature under normal pressure is 2450C. It is a high temperature and heat resistant material. Coefficient of thermal expansion (4.0-6.0) x10-6c. The thermal conductivity of polycrystalline AIN is 260W/(mk) 5-8 times higher than alumina, so it has good thermal shock resistance and can withstand extreme heat of 2200C. In addition, aluminum nitride is resistant to aluminum liquid and other molten metals and arsenic Corrosion characteristics, especially excellent corrosion resistance to molten aluminum.

Advantages and disadvantages:

The high thermal conductivity (about 320/M.K) is close to Beo and sic, and is more than 5 times that of A1203.

The coefficient of thermal expansion (4.5x10-6c) matches si (3.5-4x10-6c) and (6x10-6c);

Various electrical properties (dielectric constant, dielectric loss, volume resistivity, dielectric strength) are excellent;

The mechanical properties are good, and the Kang fold strength is higher than A1203 and Beo ceramics, and it can be sintered under normal pressure

Good optical transmission characteristics

Non-toxic

Application:

Aluminum nitride powder has high purity, small particle size and high activity. It is the main raw material for manufacturing high thermal conductivity aluminum nitride ceramic substrates.

Aluminum nitride ceramic substrate has high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, and low dielectric loss. It is an ideal large-scale integrated circuit heat dissipation substrate and packaging material.

Aluminum nitride has a high hardness, which is higher than that of traditional alumina. It is a new type of wear-resistant ceramic material, but due to its high cost, it can only be used on severely worn parts.

Utilizing the heat resistance and melt erosion resistance and thermal shock resistance of AIN ceramics, it can be used to make GaAs crystal crucibles, AI evaporators, magnetic fluid generators and high-temperature turbine corrosion-resistant parts, using its optical properties as infrared windows, aluminum nitride The film can be made. High-frequency piezoelectric components, VLSI substrates, etc.

Consulting Engineers

Give our technical sales team a call or contact us via email

Phone/Whatsapp : +86 15814459429

Email: [email protected]