Titanium alloy Plate / Sheet, Titanium supplier

Grade:

TA1,TA2,TA3,TA9,TA10,TC4,GR1,GR2,GR5,GR7,GR9,GR12

Standard:

GB/T3621-2010 ASTM B265、ASTM F67、ASTM F136、AMS 4911、ASTM B381

Surface treatment:

Pickled surface ,Shiny surface

Color:

Matt color

Titanium alloy plates & Titanium alloy sheet are widely used in chemical equipment, vacuum salt making, automobile industry, paper and textile industry, electric power industry, metallurgical industry, chlor-alkali industry, fertilizer industry, seawater desalination industry.

Titanium alloy plate / sheet specification

Thickness 0.5mm to 1.0mm x width 1000mm x height 2000mm to 4000mm

Thickness 1.0mm to 5.0mm x

width 1000mm to 1500mm x

Height 2000mm to 3500mm

Thickness 5.0mm to 30mm x

width 1000mm to 2500mm x

Height 3000mm to 6000mm

Thickness 30mm to 80mm x

width 1000mm x Height 2000mm

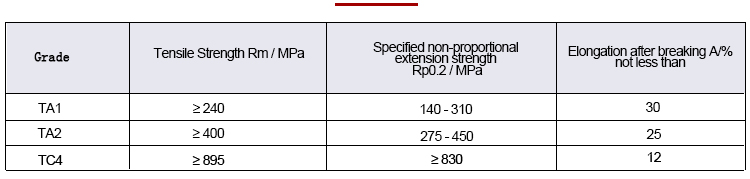

Titanium alloy plate / sheet Room temperature mechanical properties table

Titanium alloy plate / sheet manufacturing process

• Hot forging: A forging process performed above the metal's recrystallization temperature.

• Hot rolling: A rolling process performed at a temperature higher than the recrystallization temperature.

• Cold rolling: A rolling process in which the plastic deformation temperature is lower than the recovery temperature.

• Annealing: A metal heat treatment process in which the metal is slowly heated to a certain temperature, kept for sufficient time, and then cooled at an appropriate rate (usually slow cooling, sometimes controlled cooling).

• Pickling: The parts are immersed in an aqueous solution such as sulfuric acid to remove oxides and other thin films on the metal surface. It is the pretreatment or intermediate treatment of electroplating, enamel, rolling and other processes

Consulting Engineers

Give our technical sales team a call or contact us via email

Phone/Whatsapp : +86 15814459429

Email: [email protected]