Energy industry

The energy industry is the basic industry for the development of the national economy and the improvement of the people's living standards. In the past 20 years, with the rapid development of China's national economy and the continuous improvement of people's living standards, the demand for energy has continued to increase, and energy tensions have emerged. With the development of the energy industry, the energy equipment manufacturing industry has also developed rapidly, and the demand for metal and steel materials is also increasing, and it is constantly developing in the direction of high parameters, large capacity, and high efficiency.

|  |  |

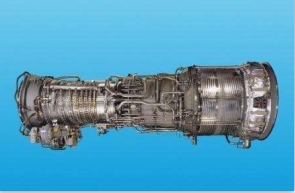

Superalloys are widely used in the energy field. In high-parameter ultra-supercritical power generation boilers for coal power, superheaters and resuperheaters must use high-temperature alloy pipes with good creep resistance, excellent oxidation resistance on the steam side and corrosion resistance on the flue gas side; In gas turbines, turbine blades and guide blades need to use high-temperature corrosion-resistant high-temperature alloys with excellent high-temperature corrosion resistance and long-term organizational stability; in the field of nuclear power, steam generator heat transfer tubes must use high-temperature alloys with good solution corrosion resistance; In the field of gasification and energy saving and emission reduction, high temperature alloys with excellent resistance to high temperature thermal corrosion and high temperature abrasion resistance are widely used.

High-temperature alloys also play a vital role in the field of atomic energy industry: fuel element cladding materials, structural materials and fuel rod positioning grids, high-temperature gas furnace heat exchangers, etc., are difficult to replace with other materials. For example, China will build 10 nuclear power plants of 600,000 kilowatts. Each 600,000-kilowatt nuclear power plant requires 100 tons of evaporator "U" shaped heat transfer tubes. In addition, there are a large number of stainless steel precision tubes and control rods for internal components of the reactor, and nuclear fuel cladding tubes.

Special alloy materials commonly used in the energy industry:

· stainless steel: 254SMO, 654SMO, F44, 2205, 2507 and other

· high-temperature alloys: GH4049

· nickel-based alloy: Alloy 59, Hastelloy B, Inconel 718, Nickel 201, Hastelloy C and other

· corrosion-resistant alloys: NS333, NS334