Aging Treatment

Aging treatment refers to the heat treatment process of metal or alloy workpieces after solution treatment, from high-temperature quenching or a certain degree of cold working deformation, at a higher temperature or room temperature to maintain their shape and size, and their properties change with time.

QPQ

QPQ process can greatly improve the wear resistance and corrosion resistance of the metal surface, while the workpiece hardly deforms.

Nitriding

Nitriding treatment refers to a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece in a certain medium at a certain temperature. Nitriding can make the surface of parts have higher hardness and wear resistance.

Carburizing

The workpiece is placed in the active carburizing medium and heated to 900-950 ℃. After enough time, the decomposed active carbon atoms in carburizing medium penetrate into the surface of steel plate, so as to improve the wear resistance of workpiece.

Sault Bath

The heat conduction speed of molten salt is much faster than other traditional methods, so the heating process of workpiece is faster, easier to control and more uniform.

High-frequency Quenching

High-frequency quenching is mostly used for surface quenching of industrial metal parts. It is a metal heat treatment method that generates a certain induced current on the surface of the workpiece, rapidly heats the surface of the part, and then rapidly quenches it.

Tempering

The quenched workpiece is reheated to an appropriate temperature lower than the lower critical temperature Ac1 (the starting temperature of pearlite to austenite transformation during heating), and the metal heat treatment process is cooled in air, water, oil and other media after holding for a period of time .

Normalizing

According to production needs, standardize production process, product form, production process, etc.

Annealing

Annealing is a metal heat treatment process, which refers to slowly heating the metal to a certain temperature, holding it for a sufficient time, and then cooling it at a suitable rate. The purpose is to reduce hardness, improve machinability; eliminate residual stress, stabilize size, reduce deformation and crack tendency; refine grains, adjust organization, and eliminate organizational defects.

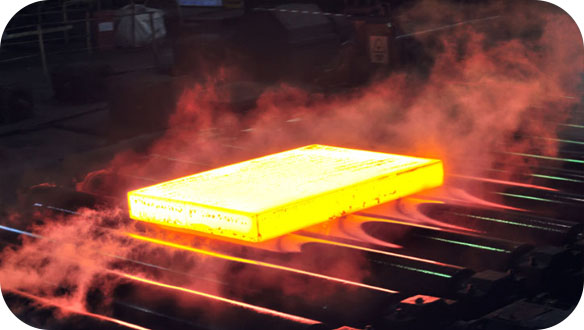

Quenching

Quenching refers to a metal heat treatment process in which a metal workpiece is heated to an appropriate temperature and maintained for a period of time, and then immersed in a quenching medium for rapid cooling.

Consulting Engineers

Give our technical sales team a call or contact us via email

Phone/Whatsapp : +86 15814459429

Email: [email protected]